Appliance Model

Modeling and implementing electrical appliances can be a demanding task. There are many parameters affecting the function and the well preservance of the devices: the power load consumption, the cycle duration of their function, their occupancy dependence and many others. In this simulation, only the most commonly used electrical appliances were used, in order to keep the balance between complexity and realism.

In the chapters below, the implementation of the general appliance model is going to be analysed. In the beginning, the basic characteristics found on every appliance will be described, in addition to their categorization according to their shifting abilities. This page will be concluded with a closer look to the implemented appliances for the TAC Energy Competition household models.

Contents

General Appliance Characteristics

There are some common characteristics that are shared by all the appliances found in a household. These are given as variables in the simulation models so that can be used easily for historical data mining or pattern discovery by anyone interested. The values of these measures differ from one type of appliances to another (For more details see each appliance category below).

- Saturation: a statistical measure, derived from diverse studies of household consumption (such as the Meregio Project), that shows the probability of an appliance of being installed in a household. Its value is between 0 and 1.

- Consumption Share: another statistical measure showing the share of an appliance in the average annual consumption load of the household.Its values are between 0 and 1, while the aggregated summary adds up to 1.

- Base Load Share: a variable showing the share of an appliance in the average household load during stand-by mode of the appliances. Its values are between 0 and 1, while the aggregated summary adds up to 1.

- Power (Watt): this variable represents the power consumption for an appliance during its operation. This value is given by the repective manufacturing companies.

- Cycle Duration (Quarter): the duration of the operation cycle of the appliance, measured in quarters of an hour.

- Occupancy Dependence: a boolean variable showing if the appliance is independent of household members presence to function of not.

- Probability Season / Weekday / Daytime: tables presenting the possibility of an appliance to function in a certain season / weekday / daytime. Its values are between 0 and 1, while the aggregated summary adds up to 1.

In addition to these, there are some auxiliary attributes helping in informing the brokers or initializing and "animating" the appliances' models.

- Name: each appliance has a name taken after from their type and the household they belong, in order to mark out from the rest of them.

- Member Of: this variable returns the name of the household in which the appliance is installed.

- In Use: a boolean variable, showing if the appliance is in use in a certain moment.

- Days: a vector with the days that the appliance is supposed to work (only for Semi Shifting Appliances, see below)

- Times of Daily/Weekly Function (private): this attribute returns how many times this appliance is functioning during a day / week.

- Operation Vector (private): a table containing the starting quarters of functioning for a week's time. This is the first scheduling, before initiating shifting and deleying due to absence of household members.

- Possibility Operation Vector (private): this vector contains the possible operation quarters of an appliance and is utilized in the case of shifting ones operation to a better suited and less costly time.

- Daily / Weekly Operation Vector (private): the variables containing the vectors with the final daily / weekly program of functioning after scheduling, shifting and so on.

- Daily / Weekly Load Vector (private): these tables contain the vectors with the final daily / weekly power load of each appliance. These vectors are aggregated in the end to summarize to the daily / weekly load of the whole household.

Appliance Shifting Capabilities

Shifting

Time-based rates increase complexity for residents but smart appliances can support the customers in their decision as well as optimize electricity consumption. The shifting algorithm presented in this section accomplishes this task.

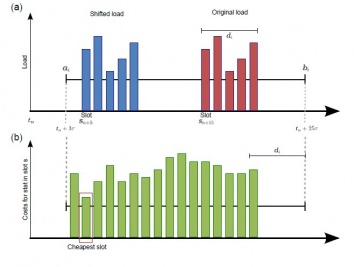

The intelligent appliance shifting algorithm works in the same way for all appliances. The simulation uses information on appliance runs from the generated load profile and, based on the original starting time, an interval [ai, bi] is determined within which the runtime of an appliance i can be shifted. Within this interval, the appliance shifting algorithm identifies the cost minimizing start slot. ai and bi are the two boundaries of the shifting interval.

Figure 1 gives an example of how the shifting algorithm changes the start time of an appliance. The duration di of the device cycle is five time slots. In part (a) it can be seen that originally the appliance is started at slot sn+15. The shifting interval for this appliance is [ai, bi]. Determination of the shifting interval is described below for each appliance individually, taking appliance specific characteristics into consideration. The algorithm then calculates the potential cost of an appliance start for each slot within the shifting interval. Costs for starting appliance i in each period are shown in part (b) of Figure 5. The appliance operation has to finish within the shifting period, hence the latest starting time is bi − di. The algorithm calculates the costs for possible start slots within the shifting interval and selects the cheapest, here slot sn+5. If the device is not already in use during the interval [sn+5, sn+5+di], the appliance cycle is shifted. If the appliance is already in use during this interval, a high penalty is added to the start costs in slot sn+5 and a new start slot is selected.

To determine the shifting interval it is important to consider customer acceptance of shifting. This individual acceptance depends on the type of service an appliance provides and has to be considered when designing the characteristics of the smart appliances. Household appliances are classified in three categories according to their technical specification and the effect (utility or disutility) a time shifting means for a household member.

- Fully Automated Appliances

- Semi Automated Appliances

- Not Shifting Appliances

Fully Automated Appliances

In this simulation, appliances that can be fully automatically shifted have a storage, so the process of delivering service and the consumption of electricity can be decoupled. Customers do not interact with these appliances, and they can be fully controlled by the shifting algorithm to consume electricity during cheap hours without any loss in service level for the consumer. An estimation of behavioral changes is not necessary for fully automatic controlled appliances.

In the following, the four fully automatically controlled appliances, refrigerator, freezer, storage warm water heater and space heating, are first described with respect to their technical function. Then their service to the customer is explained, and finally it is analyzed how the intelligent appliance shifting algorithm can shift cycles without compromising customer comfort.

Refrigerator

Firstly, a short description of the operation of the refrigerator is needed: a circulating refrigerant evaporates and absorbs heat from the inner space of the refrigerator. The vapor is then compressed. Afterwards the vapor streams through the condenser under pressure where heat is released to air in the room. The liquid refrigerant is then expanded and the cycle starts again (Stamminger et al. 2008).

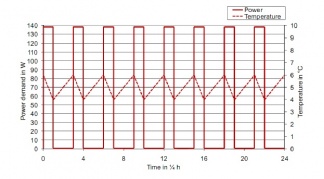

In this process, electrical energy is used to drive the motor for compression. The cooling process does not work continuously, since the refrigerator has a natural thermal storage. When a low inner temperature is reached, the compressor is turned off. Then, due to thermal losses, the inner temperature of the fridge increases. As soon as the temperature reaches an upper threshold value the cooling process starts again. Temperature inside the refrigerator varies therefore within boundaries. Due to insulation of the fridge, the inner temperature increases only slowly. A thermostat controls the process of cooling, and keeps the temperature within the preset interval so that food quality is not harmed.

Under normal conditions, when no new load is added and normal ambient temperatures prevail, the compressor operates only 20% to 35% of the time. However, operating time increases when new items are loaded (Stamminger et al. 2008). As long as the door is closed, the process is determined by thermal losses and the capacity of the compressor (Timpe 2009).

- Saturation: 99%

- Consumption Share: 9%

- Base Load Share: 0%

- Average Power Load (Watt): 140

- Cycle Duration (Quarter): 1

- Occupancy Dependence: No

Freezer

Freezer's functionality is similar with the refrigerator's, so the details are on the subchapter above.

- Saturation: 54%

- Consumption Share: 7.1%

- Base Load Share: 0%

- Average Power Load (Watt): 106

- Cycle Duration (Quarter): 1

- Occupancy Dependence: No

Storage Water Heater

In a storage water heater, an electric resistance element near the bottom of the storage heats the cold water that streams into the tank. The warm water ascends from the bottom to the top of the tank, remains in the storage tank and when required streams to the tap. The water temperature can be chosen up to 95C. Power of storage water heaters varies between 2,000 and 6,000 Watt. Storage capacity ranges from 5 to 400 liter. Depending on selected temperature, power and capacity the heating process takes between 1 and 17 hours. Appliances with large storage tanks often have a standby energy consumption after the heating process, to keep the desired water temperature (Stamminger et al. 2008).

Electric storage heaters have a very high load per appliance, what makes them very attractive for shifting. For that reason they are in use for load management already today. Typically, water is heated during night (Timpe 2009). Applying a decision support algorithms for storage water heaters could manage their load smarter in future. Cycles could be shifted to the cheapest hours during night, according to electricity generation. Additionally, the remaining appliance cycles during day hours could be shifted.

- Saturation: 20%

- Possibility to be Storage Water Heater: 40%

- Consumption Share: 13%

- Base Load Share: 0%

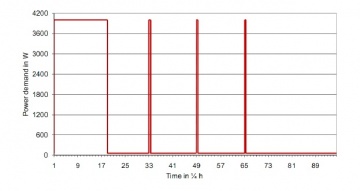

- Average Power Load (Watt): 3000

- Cycle Duration (Quarter): 8

- Occupancy Dependence: No

Space Heater

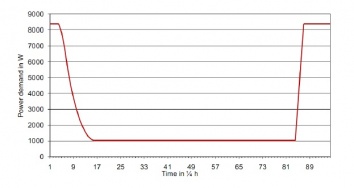

A standard storage heater has a core with a high heat retention capacity to store thermal energy. The core is surrounded by highly insulating material and has a temperature between 600C and 700C. A controller compares the actual room temperature with the desired level. If the actual temperature is too low, a fan starts to blow air through the hot core and into the room. A mixing valve controls the temperature of the air output (Stamminger et al. 2008).

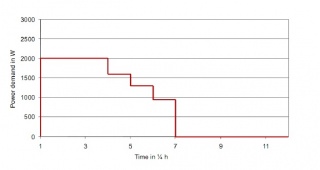

Space heating has a high load per appliance and is already in use for shifting. It shows the same benefits for smart use as storage water heating. The figure below shows a typical load profile for an electric storage heater. Electricity is consumed to heat the core at night and to operate the fan during daytime. The load for heating the core can be shifted, because storage decouples the use of electricity and the service provision.

- Saturation: 4%

- Consumption Share: 17%

- Base Load Share: 0%

- Average Power Load (Watt): 7000

- Cycle Duration (Quarter): 14

- Occupancy Dependence: No

Semi Automated Appliances

The next class of appliances includes washing machine, tumble dryer and dishwasher. These appliances can be semi-automatically controlled, i.e., their cycles can be shifted, but in contrast to refrigerator or storage space heating, interaction with the consumer is needed. A dishwasher, for example, must be loaded. Still, within certain limits the runtime for cycles of these appliances can be postponed or delayed (Timpe 2009). Again, customer comfort should not be reduced by using semi-automatic controlled appliances.

In the models, a household member can set these appliances into a ready mode (after loading them). Additionally, he can also determine the latest feasible finishing time. The use of semi-automatic controlled appliances is accompanied by a behavioral change of the residents. The origin of shifting parameters for the semi-automatically shifted appliances is described, considering the characteristics of customer preferences for their service.

Washing Machine

A washing machine does not have a storage facility, as it consumes electrical energy mainly for heating water to the desired temperature. Apart from that, for driving the drum motor and other purposes like the user interface. But often, the service delivered by a washing machine is not needed at a specific time, e.g., some customers do not care if the laundry finishes at 10 am or 7 pm, as long as they have clean and dry clothes the following day and therefore space for shifting is available.

In the following, the parameters and conditions for the shifting of a washing machine cycle are listed, starting with determination of the time at which a consumer loads the machine and followed by the determination of the shifting interval. The starting time of the washing machine cycle under a flat tariff is the basis for shifting. A household equipped with a smart washing machine can select an interval in which the machine has to run. Compared to the original situation where only a manual use was possible, three reactions are considered (they are also included as private variables in the model implementation):

- By loading the machine in the morning, a task that might have been done at another time of the day and selecting shifting interval the household resident shows a strong reaction.

- Loading the machine at the same time as before but still selecting a shifting interval is a responsive reaction.

- Loading and starting the machine at the same time as before is an unresponsive reaction.

In the simulation, for each cycle of the washing machine, one of the listed reactions is selected randomly, in order to determine the loading point at which the machine is filled and ready to run. After loading, the customer can choose four different modes, each defining an interval in which the machine has to start and finish. The idea for these modes is based on survey results of Mert and Tritthart (2008), where different designs of smart appliances have been proposed to customers. One of the most widely accepted scenarios was that users define when the operation has to be finished latest. The four modes (they are also included as private variables in the model implementation) a household resident can choose are:

- Mode one: the laundry has to finish within five hours from the loading point.

- Mode two: finish within five to ten hours.

- Mode three: finish in more than ten hours, but at the same day.

- Mode four: finish laundry between loading point and end of day.

Mode one, two and three are mutually exclusive.

Several constraints have been introduced in order to take customer preferences for the service of a washing machine into account. A washing machine cycle cannot be shifted to night hours (Mert and Tritthart 2008). Noisy runs and the customer preference to take the laundry out of the machine close after the run are the motivation for this restriction.

Statistics on German sleeping habits set the probability of the time at which a washing machine cycles must terminate. It is assumed, that the laundry has to be finished at least 30 minutes before household residents go to bed. One quarter of the German population goes to bed before 10 pm, two thirds before 11pm (Meier 2004; Allianz Deutschland AG 2009). Accordingly, in the simulation one quarter of the appliance cycles terminate before 9:30 pm and two thirds before 10:30 pm. However, even for a cycle that is not restricted by sleeping behavior, a washing machine has to finish at the same day. It is assumed that this restriction still allows residents to have clean laundry which can by dried until the following day and so the utility of the service the washing machine provides is not decrease due to shifting.

When selecting a mode, it is assumed that household residents prefer to take the laundry out of the machine close after the run. Selection of the mode is done by checking the presence of the household residents using the occupancy profile from the first part of the model. A mode is available for selection if at least one person is at home during the two hours after the end of the defined period, so someone will be able to take the wet laundry out of the machine. If more than one mode is available it is randomly determined which mode is chosen by the customer.

- Saturation: 97%

- Consumption Share: 3.5%

- Base Load Share: 2%

- Average Power Load (Watt): 600

- Cycle Duration (Quarter): 7

- Occupancy Dependence: Yes, a member of the household must be present to unload the clean clothes.

Dryer

Dryers are attractive appliances for load shifting due to their high power consumption. In a drying cycle, electrical energy is needed mainly to evaporate the water from the laundry, but also to rotate the drum, drive the fans and other components (Stamminger et al. 2008). Shifting capacity for a dryer has its origin in the flexibility the customer have regarding the finishing time of the dryer’s service. A fully automatic smart operation is difficult; instead customers have to be involved in the operation (Timpe 2009).

In the simulation of household load profiles, a dryer operates after the use of a washing machine. If, according to the load profile under a flat tariff, a dryer is used after a washing machine, it operates after the same washing cycle in the shifting simulation. It is assumed that, to avoid mouldy laundry, a resident unloads the washing machine and puts the wet laundry into the dryer as soon as the washing cycle finishes and he is at home. Hence, the first time slot in which a resident is present after the end of the shifted washing cycle is selected as the loading point of the dryer and defines the lower boundary ai of the shifting interval.

In the simulation it is assumed that dryers can be operated in a smart mode, which is designed based on the results of the survey of Mert and Tritthart (2008). Customers can decide to start the dryer immediately, or they can choose a smart mode with a shifting interval of three hours where the dryer is started automatically by the appliance algorithm: bi = ai + 12. A strong increase in shifting availability could be reached by combining washing machine and dryer into one single appliance (Timpe 2009).

- Saturation: 42%

- Consumption Share: 2.5%

- Base Load Share: 1.5%

- Average Power Load (Watt): 1410

- Cycle Duration (Quarter): 6

- Occupancy Dependence: Yes, a member of the household must be present to load the dryer with clean clothes.

Dishwasher

Out of the appliances that can be shifted semi-automatically, a dishwasher is the most interesting one, because automating its operation is highly accepted among end consumers. In addition, its high average energy demand per cycle makes it an attractive target for optimization (Timpe 2009). Furthermore, the operation is very flexible as consumers mostly do not care when exactly the appliance works, so even a use during the night might be possible. In contrast to the washing machine, a dishwasher must not be emptied out close after operation. Dishes can be left inside without influencing the quality of the service. The shifting interval for dishwashers can be expected to be the largest for all semi-automatic devices. During a dishwasher cycle, electricity is needed mainly for heating water, but also for driving the circulation pump motor (Stamminger et al. 2008).

In the simulation, the starting time for a dishwasher cycle from the load profile under a flat tariff is chosen to be the loading point for the smart dishwasher. At the loading point the dishwasher is filled and ready to run, so it defines ai the lower boundary of the shifting interval. The resident then either starts the dishwasher directly or selects a “smart

start”. Probability for the use of a smart start has to be assumed. The smart start sets the latest end of the cycle, which is the upper boundary for the shifting interval bi. Three smart start modes can be selected for the dishwasher:

- Mode one: operation has to finish within 5 hours.

- Mode two: operation has to finish within 10 hours.

- Mode three: machine has to finish until the next day at 6am.

The design of these modes is based on the dishwasher’s flexibility; cycles can often be shifted without violating customer comfort. Selection of a mode for a cycle is based on the occupancy profile of the residents from the first part of the model. Mode one and two can be selected, if during 2.5 hours after the end of the respective mode someone

is at home. If both are available according to the occupancy profile, a mode is randomly chosen with an equal probability. Mode three can always be selected when a customer uses smart mode and is applied when neither Mode one nor Mode two are available. For the selection of the modes it is assumed, that residents that are at home during the day, want the dishwasher to finish at the same day, to load it again, therefore they select Mode one or two. Constrained by the loading point which is determined by the original start slot, and the finishing time, defined by the selected mode, the algorithm selects the cheapest start time.

- Saturation: 66%

- Consumption Share: 3.7%

- Base Load Share: 0%

- Average Power Load (Watt): 530

- Cycle Duration (Quarter): 9

- Occupancy Dependence: Yes, a member of the household must be present to load the dishwasher with dirty dishes.

Not Shifting Appliances

Not all household appliances are included in the load shifting model presented here. Individually modeled appliances like stove, light and instantaneous electric water heater are used on demand. They have in common that electricity is needed exactly at the moment when the appliance provides its service. Shifting of these appliances is only possible when consumers change their schedule. An algorithm cannot support shifting. Moreover, a delay in the service provided by these appliances decreases customer utility. If, for instance, a resident is hungry and wants to cook, he does usually not want to wait until electricity is cheaper. For this reason Timpe (2009) classifies a stove as not suitable for shifting.

The categories "‘others"’, "‘consumer electronics"’, and "‘information and communication technology"’ contain several appliances. Some of them might be available for shifting, e.g. air conditioning (others) or notebook (ICT) , but, as they only have a small share on total energy consumption, their potential for shifting is limited and they are not included as shiftable appliances in the simulation. Other appliances, e.g. TV, radio (consumer electronics) or coffee machine (others) are used on demand and are not modeled for the aforementioned reasons. A circulating pump has a large share of the total electricity consumption of a household. It pumps the water in a central heating system, and it is running as long as warm water is needed in the house. Shifting is only possible manually when consumers change their heating schedule. An algorithm supporting shifting can not be applied.

Stove

- Saturation: 85%

- Consumption Share: 8.1%

- Base Load Share: 0%

- Average Power Load (Watt): 1840

- Cycle Duration (Quarter): 2

- Occupancy Dependence: Yes, a member of the household must be present.

Consumer Electronics

- Saturation: 98%

- Consumption Share: 13%

- Base Load Share: 35%

- Average Power Load (Watt): 100

- Cycle Duration (Quarter): 1

- Occupancy Dependence: Yes, a member of the household must be present.

Information and Communication Technology (ICT)

- Saturation: 98%

- Consumption Share: 5%

- Base Load Share: 60%

- Average Power Load (Watt): 150

- Cycle Duration (Quarter): 1

- Occupancy Dependence: Yes, a member of the household must be present.

Instant Water Heater

- Saturation: 20%

- Possibility to be Storage Water Heater: 60%

- Consumption Share: 13%

- Base Load Share: 0%

- Average Power Load (Watt): 12000

- Cycle Duration (Quarter): 1

- Occupancy Dependence: Yes, a member of the household must be present.

Circulation Pump

- Saturation: 92%

- Consumption Share: 6%

- Base Load Share: 7%

- Average Power Load (Watt): 90

- Cycle Duration (Quarter): 19

- Occupancy Dependence: Yes, a member of the household must be present.

Lights

- Saturation: 100%

- Consumption Share: 8%

- Base Load Share: 0%

- Average Power Load (Watt): 350

- Cycle Duration (Quarter): 8

- Occupancy Dependence: Yes, a member of the household must be present.

Others

- Saturation: 100%

- Consumption Share: 4.1%

- Base Load Share: 20%

- Average Power Load (Watt): 500

- Cycle Duration (Quarter): 1

- Occupancy Dependence: Yes, a member of the household must be present.

Functions

General Functions

- Initialize (private): same as in person and household agents, this is the constructor function of the Repast Agent(s) responsible for the Appliances' Simulation. It takes as inputs the name of the appliance, in order to distinguish them with each other and the configuration file parametes. After collecting every detail necessary, next a fully operational electrical appliance is created and installed inside a household.

- Get Probability: this function returns the possibility of an appliance to work at a certain session, weekday and daytime.

- Fill Season / Weekday / Daytime (private): the functions used to fill the HashMaps of the possibilities of an appliance to work at a certain session, weekday and daytime.

- <u

- Fill Daily / Weekly Function (private): At the beginning of each day (or each week), each appliance agent is using its operational patterns and provide the quarters that is functioning every day of the week. Each appliance's planning is totally independent from any other one, cause there are diverse factors playing important role in the distribution.

- Refresh(private): this is the function that works synchronously in every household in the simulation. With each passing day or week the appliance's status is refreshed: some appliances start working, others stop and others are put in stand-by mode.

- Show Status: By using this function, we can see the household status for that particular moment (tick) or for that (whole) day: where are the members of the household, which appliances are working and their consumption etc.

Shifting Functions

- Fill Days (private): randomizer function that changes every week the operation days of the appliances (only for the semi automated appliances)

- Create Daily / Weekly Operation Vector (private): functions that regulate the operation starting points during a day / week.

- Create Possibility Operation Vector (private): this is the function that gives all the available timeslots that an appliance can move its operation in order to have better and less costly result.

- Shifting Function (private): the function utilizing the appropriate algorithm for the shifting of the smart appliances installed in case of Real-Time Pricing environment.

Configuration Parameters

- Saturation of each appliance

- Daily / Weekly Times Of Usage (available only in some appliances)

- Percentage of Operation (available only in some appliances)

- Percentage of Instant or Storage Water Heater